WinPIPE – Pipe Stress Analysis Software for Future

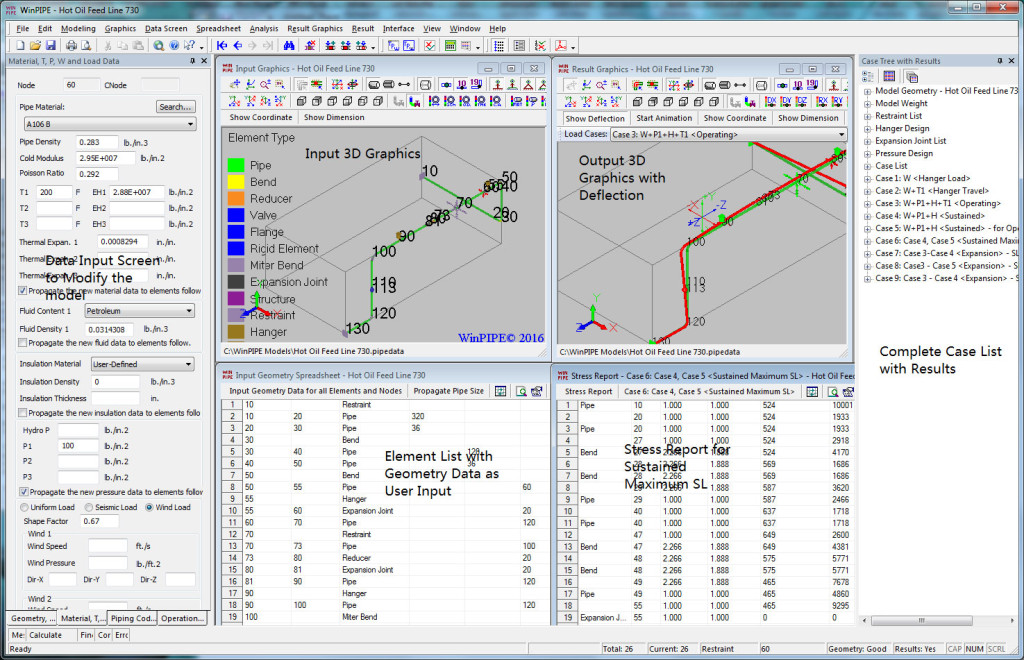

WinPIPE is a new generation of pipe stress analysis program. The primary goal of its design is to provide graphical and block operations for pipe-layout modeling, which will free users from bondage of entering component data one by one. Another goal is to synchronize all data so that users can build a model, set up load cases, calculate stresses and generate reports all in an integrated work environment.

Based on Windows platform, WinPIPE is very easy to use. Although there is a large set of graphical and block operations, and many new functions in the program, users should feel at home since all these operations and functions are designed to make pipe-layout modeling simple and easy. Once getting the hang of it, there would be no turning back to other “legacy” programs designed more than 30 years ago in PC-DOS era (too difficult to keep up with new features and almost impossible to add graphical and block operations).

In contrast, by applying modern computer technology to pipe stress analysis, WinPIPE delivers unique features as never before:

- Integrated Work Environment – Benefits:

- Both input (layout geometry) and output (deflections, stresses and so on) can be opened side by side for check and verification

- If a node in output needs attention (e.g. an overstressed node), one click jumps to input model at the node’s location

- All data for a job is in a single file, including data for geometry, load cases and output

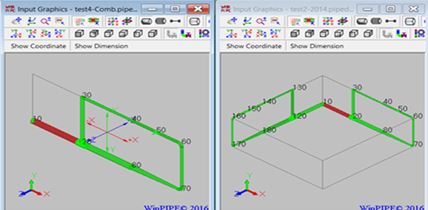

- Multi-Job Processing Capability – Benefits:

- Two jobs or more can be opened side-by-side for comparison and operations

- If you want a section of the model in job A, you can copy and paste it to the model in job B, and vice versa

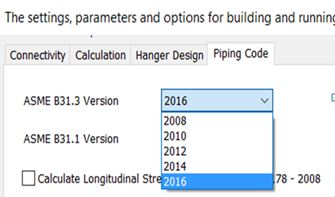

- Multi-Version Support for B31.3 (2008 to 2016) – Benefits:

- Five B31.3 versions are in the same program, not one version per one program

- No compatibility issue. After running B31.3-2016, you can run B31.3-2008 to compare results

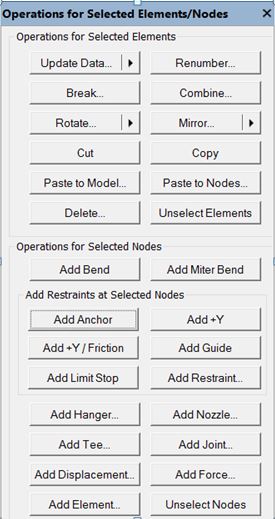

- Graphical and Block Operations – Benefits: (This will drastically improve productivity of pipe stress engineers)

- A group of elements are selected graphically, and operations are applied to them to change their properties, such as pipe size

- A group of nodes are selected graphically, and operations are applied to them to add +Y supports, for example

- Improved Load Case Analyzing Facilities – Benefits:

- Hot sustained cases can be setup easily according to the corresponding operating cases

- Maximum SLs are obtained using “Maximum SL” case

- Maximum SLs are used in expansion/fatigue cases for liberal allowable to comply with B31.3 code requirements

- See Support section for explanation

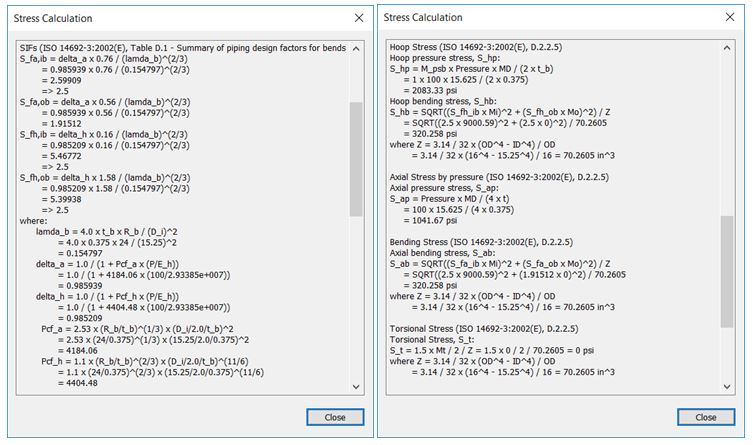

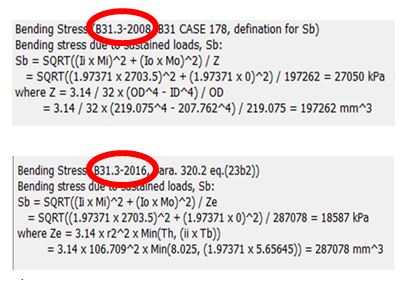

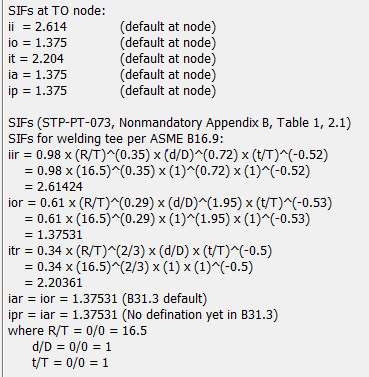

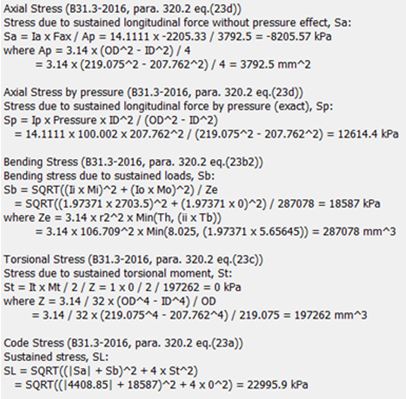

- SIF/SSI and Stress Calculation Details – Benefits:

- Any double about results? Or ever wondering about how stresses are calculated? They are just a click away

- Code version, paragraph, section, equation number and calculating steps are all listed for verification

With these capabilities, WinPIPE will have a great impact on daily works of pipe stress engineers by increasing their productivity, making their models compliant with piping code requirements, and having a high degree of confidence in the results of their analysis.

Like all new products, we will continue to improve and enhance WinPIPE. Since the program is designed by engineers and it is for engineers, we welcome all comments and suggestions, and will set priority to include feature requests accordingly. Because of flexible programming and data structures of WinPIPE, we can quickly accommodate user’s requests to the program, either for customization or for general extension.

Based on recent feedback, we are adding new features, that will be available very soon:

- WinPIPE Demo: Free version with limited capabilities:

- pipe code: B31.3 – 2008 to 2016 and B31.1 – 2012

- maximum number of elements: 30

- pipe sizes: 6″ and less

- materials: B31.3-2012 carbon steels and B31.1-2012 carbon steels

- maximum number of load cases: 20

- Support for FRP code ISO 14692 – 2002 (see SIF and Stress Calculation Details below)